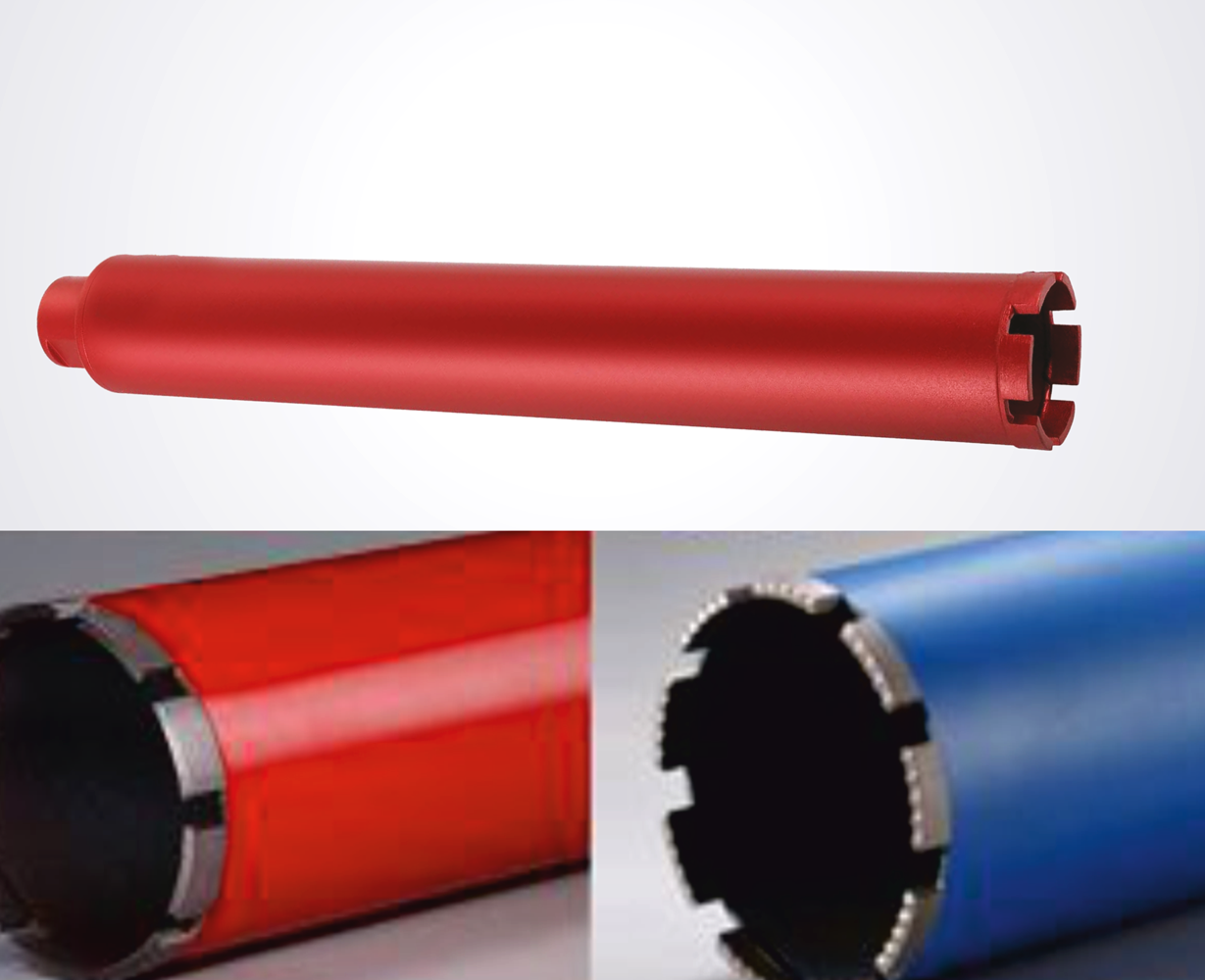

DIAMOND CORE DRILL BITS

STB a professional diamond core bits factory involved in diamond core drill bits manufacturing since 1987 specializing in the manufacturing of wet diamond core bits, dry diamond core drill bits, crown diamond core drills bits, core drills for granite marble & concrete. Spare Waves type Diamond segments for concrete core bits re-tipping is also available for wholesale.

• For hole in Hard Granite, Marble, Concrete

• Size: 6.5mm to 100mm Dia

• Suitable for Angel Grinder Machine/Normal Drill Machine

• Special metal bond for longer life

• Chrome, powder coated finish available.

• Special stud for use in drill machine

DIAMOND CORE DRILLS

• Thread Size: 1¼ UNF

• Total Length: 450mm

• Working Length: 400mm

• Wave type segment for high Performance

• Segments made from special bond for extra life

| Size Dia (mm) | Segment in 1 pc |

| 52mm | 4pcs |

| 65mm | 5pcs |

| 77mm | 6pcs |

| 90mm | 7pcs |

| 102mm | 8pcs |

| 127mm | 10pcs |

| 152mm | 12pcs |

| 162mm | 13pcs |

| 180mm | 14pcs |

STB WAVE STYLE CORE DRILL SPARE SEGMENT

• Available in different size as per requirement

• Special diamond bond for longer life

• Wave type shape for high performance

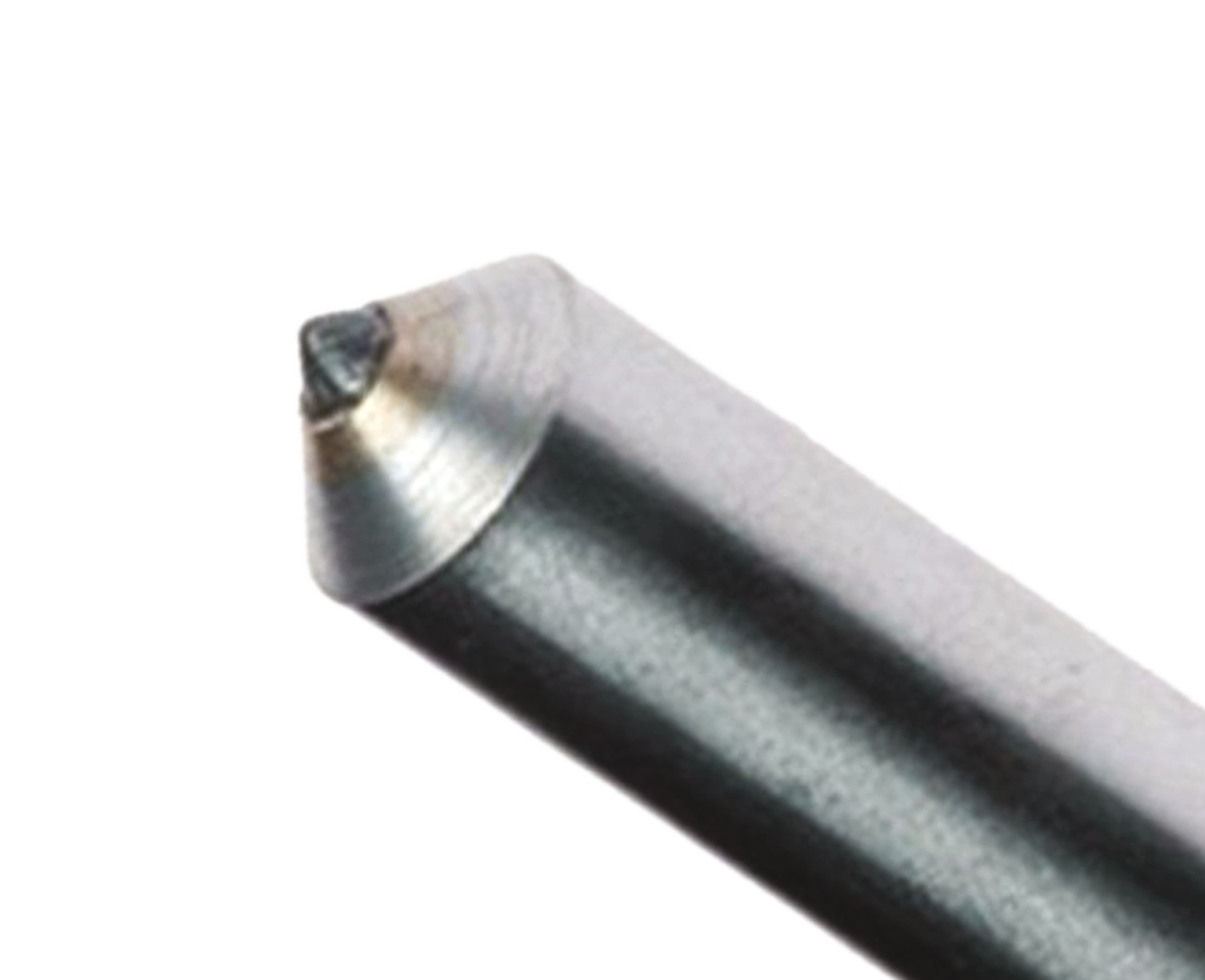

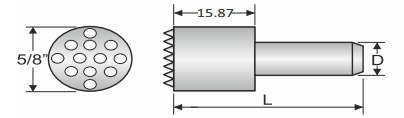

SINGLE POINT DIAMOND DRESSER NATURAL & BRUTED POINT

STB manufacturers single point bruted diamond dresser with high quality selected congo round diamonds.

We select each & every diamond in according with quality & size.

We have three different grades of diamonds A/B/C available from 0.16 CT to 8.00 CTs. It is normally based on the required grinding finish, machine, working parameters, size & style of wheels.

GUIDELINES

• Diamonds are sensitive to heat so considerable core should be taken in mounting the diamond dresser.

• The dresser must be clamped rigidly in place to avoid vibration once dressing begins.

• The diamond holder should be an angel of 5-15° to the direction of wheel so that it appears to be trailing.

• The maximum depth of cut achieved per dressing pass is 0.03mm or on fine grit wheels approx. 0.005-0.01mm.

Fed Rate for Grinding Wheels

| Grinding Wheel | Feed rate |

| 30-46 | 0.60-0.30 |

| 50-120 | 0.30-0.10 |

| 180-320 | 0.10-0.02 |

Application

Single point dressers are used for OD and/or side dressing of conventional wheels. They can be used on Cylindrical Grinders, Surface Grinders, Tool and Cutters.

Sizes

• Standard shanks: ½”x6" up to 3.50 cts and 5/8"x6" over 3.50 cts.

• We also offer customized shanks to match your application.

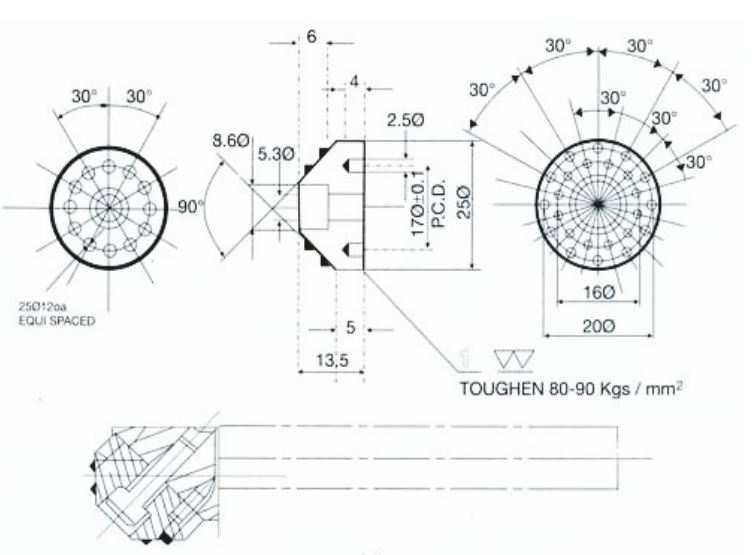

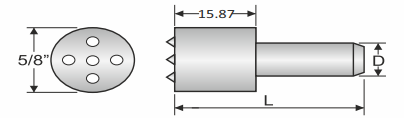

INDEXABLE CROWN TYPE DRESSERS (MULTI-POINT)

STB indexable crown type dresser are recommended of cylindrical grinders and for fine tuning of larger wheels we use sharp industrial diamond for longer life.

Advantages

• A large area of the wheel is dressed more efficiently in a relatively shorter time than a single point dresser.

• The diamonds can be completely used and resetting is redundant.

• Crystal shape gives finer finish on the wheel.

• Indexable crown type dresser are best for side dressing.

• The work load on the diamond divided which results last longer life of diamond.

Sizes

• 24D - wheel size upto 600mm

• 36D - wheel size above 600mm

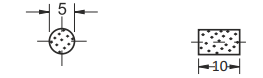

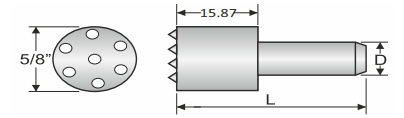

GRIT IMPREGNATED DRESSERS

Diamond grit impregnated dressers are manufactured from crushed diamonds.

These dressers are more economical because of their low initial cost and their resistance to shock and impact which prevents shattering.

The feed rates could be double those used with single point dressers.

The size of the diamond grit particles should be matched to the grit size of the grinding wheel.

These dressers demand greater care in selecting the correct dresser for a given application.

The bond and diamond grit size used are both variable according to the type of grinding wheels to be dressed.

The size of the diamond grit particles should be matched to the grit size of the grinding wheel.

Guidelines

• Good quality of coolant should be used while dressing

• Cutting face of the dresser should be set at an angle of 90° to the grinding wheel to be dressed.

• Feed rate should be double then normal single point dresser.

• The depth of cut should be approx. 0.01mm for finishing approx. 0.02mm for rough grinding.

Application

These dressers can be used where longer life, frequent dressing cycle, consistent surface finish are required. They are suitable for use on Centerless Grinders of larger diameters and lengthy dressing cycles.

Sizes: Customized to customer requirements

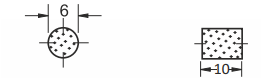

| Catalog Number | Diamond Section | Diamond size in Micron | Bond |

| DG-4 |

|

600 | W-WC |

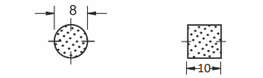

| DG-5 |

|

600 | W-WC |

| DG-6 |

|

600 | W-WC |

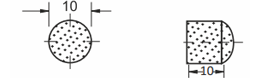

| DG-8 |

|

1000 | W-WC |

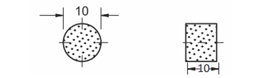

| DG-10 |

|

1000 | W-WC |

| DG-10-P |

|

1000 | W-WC |

| DG-12 |

|

1000 | W-WC |

| DG-12-P |

|

1000 | W-WC |

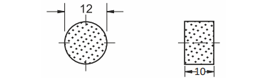

DIAMOND COATED FILE

We made these files from synthetic diamonds in Fine/Med/Coarse grits. These files are having diamond coating therefore these are used for filing hard and brittle materials. These files are ideal for alloy steel, tungsten carbide, glass, tool steel, semi-precious stones, hard stones, die mould, saw blades, cutting tools, carbide insert and wherever hard grinding and sharpening is required. These files are available in various shapes to cover all forms of engravings and material removals.

Available in: Taper Flat, Square, Hand Flat, Half Round, Round, Three Square, Square and Knife

Key Features: As they are thinner, they can be used in tighter spaces than normal files.

Size:

Total Length: 160mm

Coated Length: 80mm

Thickness: 3mm

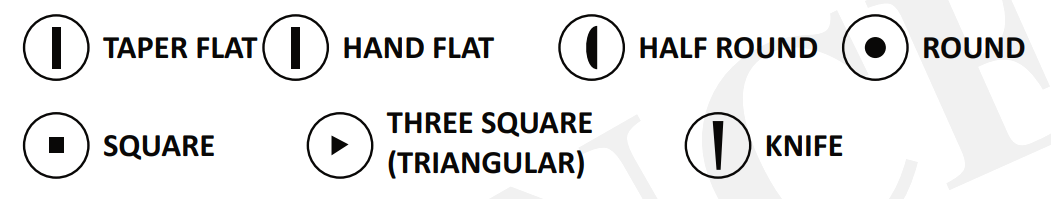

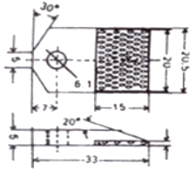

WHEEL DRESSER CUTTER

| Nominal Size of Wheel Dresser | Cutter and washer Dimensions | Bore Dia d ± 0.12 | b Max | Base Circle Dia d, ± 0.2 | No. of Cutters | No. of Washers | ||

| Outside Dia D ± 0.25 | Thickness | |||||||

| Cutter | Washers | |||||||

| 0 | 30 | 2 | 0.65 | 6.35 | 10 | 21 | 4 | 2 |

| 1 | 38 | 2 | 1.0 | 12.7 | 11.9 | 26.5 | 4 | 2 |

| 2 | 60 | 3 | 1.0 | 15.1 | 23 | 6 | 6 | 2 |

• Made from special colled rolled Steel

• Hardened & Tempered fully guaranteed.

• Available in black finish.

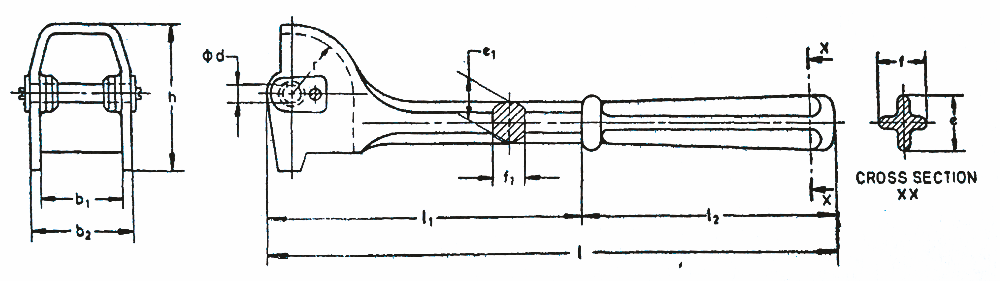

HANDLE FOR EMERY WHEEL DRESSERS

The STB Wheel Dressers & Cutters are used for maintaining the sharpness and longevity of your solid abrasive wheels. The dressers are designed with a powder-coated body and a cast iron handle that provides a comfortable grip. The star-shaped teeth of the cutters are designed to effectively expose new grains and provide a fresh unloaded surface on the wheel, ensuring that the abrasive wheel cuts cleanly and efficiently. The cutters are also available as a set of 4 spare parts, allowing you to maintain the sharpness of your abrasive wheel over time. Our Wheel Dressers & Cutters are an essential tool for keeping your solid abrasive wheels in top working condition.

| Nominal Size of Wheel Dresser | I | I1 | I2 | r | d | b1 | b2 |

e1 ~~ - |

f1 ~~ - |

h |

| 0 | 285 | 155 | 130 | 30 | 5 | 25 | 40 | 25 | 16 | 63 |

| 1 | 285 | 155 | 130 | 30 | 8 | 25 | 40 | 25 | 16 | 63 |

| 2 | 340 | 190 | 150 | 45 | 10 | 48 | 63 | 30 | 20 | 85 |

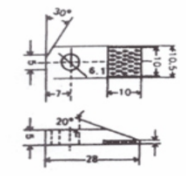

CHISEL TYPE DRESSERS

Chisel / Profiling Dressers

• Best tools for profiling of grinding wheel.

• These tools are made from very high quality natural diamonds under strict quality checks.

• STB can offer Chisel dressers with included angle ranging from 30° to 90° and the radius 0.125mm to 0.500mm.

• These dresser are used for generating concave and convex radil on all wheel sizes for contour dressing on center less grinders and for angle head dressing.

• STB can offer customized Chisel dressers as per customer drawing

BLADE TYPE DIAMOND DRESSERS

Blade dressers use thin natural diamond needle which are more economical than single point diamonds. Blade type dressers are designed to utilize their full life span with minimum deterioration of form and tolerances. They are developed on the "fix and forget" principal.

Unlike single point dressers which are more or less independent of the grinding wheel specifications, blade dressers have to be selected considering the grinding wheel specifications and conditions of dressing.

Advantages

• Blade type dressers are highly economical compared to single point dressers

• They have higher form retention capability

• Minimum in-process service attention compared to any other dresser due to their self-wearing property.

• They are ideal for optimum dressing conditions. In turn provide higher dressing accuracy.

• Greater flexibility in selection from a wide range of varieties of dressers to suit different grinding wheel specifications and grinding conditions.

Applications

Blade Type Dressers are ideal for applications where consistent surface finish and longer life are important. They can be used for Profile Generation (Male and Female), Side Dressing, Angular Dressing, OD Straight Dressing.

| Size | Dimensions | |

| FA-090 FA-110 FA-140 FA-GRIT |

|

20 x15 x X |

| FA-075 FA-090 FA-110 FA-140 FB GRIT |

|

10 x 15 x X DIMENSIONS OF THE DIAMOND PLATE 0.75 mm 0.90 mm 1.10 mm 1.40 mm 18 to 20 GRIT |

| FA-090 FA-110 FA-140 FA-GRIT |

|

15 x 10 x X DIMENSIONS OF THE

DIAMOND PLATE 0.90 mm 1.10 mm 1.40 mm 18 to 20 GRIT |

| FA-075 FA-190 FA-110 FA-140 FD GRIT |

|

10 x 10 x X DIMENSIONS OF THE

DIAMOND PLATE 0.75 mm 0 .90 mm 1.10 mm 1.40 mm 18 to 20 GRIT |

DIAMOND PASTE

STB offers high-grade diamond lapping paste that is manufactured using qualitative diamond powder along with appropriate components, in order to ensure efficient application and achieve the desired quality of results. Available in both oil as well as water-soluble mediums, our diamond lapping paste finds application for quick polishing of all kinds of hard metals and for rendering a superior degree of finish to them. STB range of diamond lapping powder is extensively demanded by manufacturers of dies, seals, moulds, components and other similar industries where a high degree of polish is required.

Our diamond lapping powder can be made available in fine, medium and rough pastes and is packed in syringes of 5 C.C., so as to ensure easy and safe handling. To ascertain efficient application and optimum results, the work conditions and the stock to be removed are taken into consideration to determine the appropriate grade.

Applications

Wire drawing: Tungsten carbide dies, rolls, guides, etc. Electronics -Semi-Conductor wafers, laser rods. tape heads, computer memory discs, radar tracking discs, etc.

Metal Working: General production components, mechanical seals, bearing seats & pivots, ceramic components, fuel injection valves hydraulic & pneumatic components, pump glands, etc.

Ship building: Diesel injector valves, pump glands & seal faces, aluminum mirrors, etc.

Optics: Contact lens moulds, stainless steel mirrors, Perspex prisms, etc.

Tool Room: Press tools, tablet punches, test blocks, gauges, plastic moulds, slide surface, etc.

Laboratory: Metallurgical, Geological and Refractory specimens, Crystallography, Fibre optics, etc.

Aeronautics: Seal plates of jet engines, hydraulic valves, spacers, etc.

Petrochemicals: Pump faces, valve seats, spinnerets, wear blocks, etc.

| Grades | Code No. | Colour Code | Guide for recommended use |

|

D-1 D-2 |

White | Metallographic finish on steel & very high finish of steel and hard metals. |

| Grey | For finish Tungsten Carbide dies, mirror polish steel and hard steel moulds and gauges etc. | ||

|

D-3, D-4 D-5, D-6, D-7 |

Green | Mirror polish and high finish on tungsten carbide, finest polish on sapphire, ruby, steel etc. |

| Yellow | Medium Polish on steel, Tungsten Carbide | ||

|

D-10, D-14 | Orange | Removal of working scratches on steel and prepublishing of steel and soft metals. Medium polish on Tungsten Carbide, pre-polishing on sapphire and ruby. |

|

D-15, D-20, D-25 D-30, D-40 |

Pink | Rapid stock removal with better finish on steel and Tungsten Carbide |

| Brown | Uniform stock removal on steel, Generation of uniform surface and medium cutting on Tungsten Carbide. | ||

|

D-50, D-60 D-80, D-100 |

Red | Fast Stock removal on Tungsten Carbide and any hard metal & enlarging the bore of Drawing Dies. |

| Black | For Speedy cutting on Tungsten Carbide & Steel and any metal. | ||

| Diamond Compound is available in standard & high concentration in 5 gm syringe. | |||

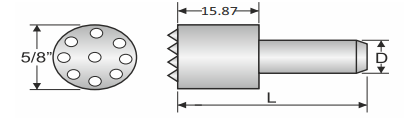

CLUSTER TYPE DRESSERS

Cluster type diamond dressers made from small special quality crystal character, rough diamonds. We used special bond for sintering these diamonds for longer life. These dressers are more economical than single point diamond dressers. The diamonds can be fully utilized without re sharpening. These dressers can give rapid dressing without scoring and produce a consistent even surface on the grinding wheel.

Guidelines

• Angle should 90° to the grinding wheel.

• Normal wheel speed should be used with smaller cutes.

• Good quality of coolant should be used.

Applications

• Ideal for coarse or rough dressing of grinding wheels in sizes up to 80 grit.

• Ideal for grinding to eliminate imbalance.

| Size | CT. WT (approx.) | Code No. |

| 5/D | 1.25 |

|

| 7/D | 1.75 |

|

| 9/D | 2.00 |

|

| 12/D | 3.50 |

|

| Classifications | MICRON | Code No. | Colour Code | Guide for recommended use |

| For operations requiring precise finishes and tolerances |

|

D-1 | Blue | Metallographic finish on steel & very high finish of steel and hard metals. |

| D-2 | Blue | For finish Tungsten Carbide dies, mirror polish on steel and hard steel moulds and gauges etc. | ||

| Final finishing grades for moulds dies seals, flat lapping and production lapping |

|

D-3, D-4 | Green | Mirror polish and high finish on tungsten carbide, finest polish on sapphire, ruby, steel etc |

| D-5, D-6, D-7, D-8 | Yellow | Medium Polish on steel, Tungsten Carbide and Diamond | ||

| D-10, D-14 | Orange | Removal of working scratches on steel prepolishing of steel and soft metals. Medium polish on Tungsten Carbide, Pre-polishing on sapphire and ruby | ||

| Grade for pre-finishing hard metallic and non metallic materials tungsten carbide ceramics etc. |

|

D-15, D-20, D-25 | Pink | Rapid stock removal with better finish on steel and Tungsten Carbide |

| D-30, D-40 | Brown | Uniform stock removal on steel, Generation of uniform surface and medium cutting on Tungsten carbide | ||

| Maximum stock removal for hogging and rigging operations in extremely hard materials |

|

D-50, D-60 | Red | Fast Stock removal on Tungsten Carbide and any hard metal & enlarging the bore of Drawing Dies |

| D-80, D-100 | Black | For Speedy cutting on Tungsten Carbide & steel and any metal |

Diamond Compound is available in standard & high concentration in 5 gm syringe packing in oil & water soluble.

| GRADE MIC. SIZE | COLOUR CODE |

| 1/2-1 1-2 1-3 2-4 2-6 |

WHITE |

| GRADE MIC. SIZE | COLOUR CODE |

| 4-8 8-12 15-25 20-30 30-40 40-60 |

YELLOW |