GRIT IMPREGNATED DRESSERS

Technical Specification

Diamond grit impregnated dressers are manufactured from crushed diamonds.

These dressers are more economical because of their low initial cost and their resistance to shock and impact which prevents shattering.

The feed rates could be double those used with single point dressers.

The size of the diamond grit particles should be matched to the grit size of the grinding wheel.

These dressers demand greater care in selecting the correct dresser for a given application.

The bond and diamond grit size used are both variable according to the type of grinding wheels to be dressed.

The size of the diamond grit particles should be matched to the grit size of the grinding wheel.

Guidelines

• Good quality of coolant should be used while dressing

• Cutting face of the dresser should be set at an angle of 90° to the grinding wheel to be dressed.

• Feed rate should be double then normal single point dresser.

• The depth of cut should be approx. 0.01mm for finishing approx. 0.02mm for rough grinding.

Application

These dressers can be used where longer life, frequent dressing cycle, consistent surface finish are required. They are suitable for use on Centerless Grinders of larger diameters and lengthy dressing cycles.

Sizes: Customized to customer requirements

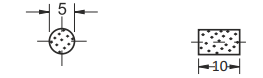

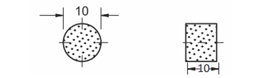

| Catalog Number | Diamond Section | Diamond size in Micron | Bond |

| DG-4 |

|

600 | W-WC |

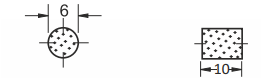

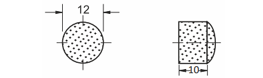

| DG-5 |

|

600 | W-WC |

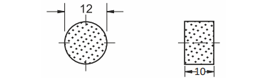

| DG-6 |

|

600 | W-WC |

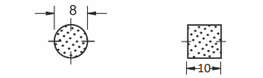

| DG-8 |

|

1000 | W-WC |

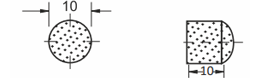

| DG-10 |

|

1000 | W-WC |

| DG-10-P |

|

1000 | W-WC |

| DG-12 |

|

1000 | W-WC |

| DG-12-P |

|

1000 | W-WC |